Blog

Vibration Resistance of LED Street Lights – Understanding the ANSI C136.31 Vibration Test

Vibration Resistance of LED Street Lights – Understanding the ANSI C136.31 Vibration Test

Modern LED street lights face far more than rain, heat, and dust. One of the most overlooked threats to their long-term performance is mechanical vibration—especially when luminaires are installed on bridges, highways, overpasses, or poles exposed to heavy wind and traffic loads. To guarantee reliability and safety, manufacturers follow a rigorous industry standard: ANSI C136.31 Vibration Test.

This article explains why vibration resistance matters, what ANSI C136.31 requires, and how LED street light designs can meet or exceed these vibration performance levels.

Why Vibration Resistance Matters for LED Street Lights

Street lighting poles constantly experience mechanical stress from:

High-speed traffic creating ground vibration

Wind-induced oscillation causing the pole to sway

Railway vibration (for lights installed near tracks)

Bridge expansion and movement

Storms or strong gusts of wind

Poorly designed luminaires can suffer from:

Loosened screws and brackets

Cracked housings

Internal PCB component failure

Shortened LED driver lifespan

Flickering or complete failure

Because outdoor lighting is often mounted several meters high, vibration damage also poses safety risks, including falling fixtures or pole fatigue.

What Is ANSI C136.31?

ANSI C136.31 is a key North American standard defining the vibration requirements for LED roadway and area lighting. The test simulates real-world vibration conditions to ensure the luminaire remains structurally and electrically stable over its expected life.

Two Main Vibration Levels in ANSI C136.31

| Vibration Level | Typical Application | Description |

|---|---|---|

| 2G – Normal Vibration | Residential areas, standard roadways | Simulates moderate vibration from wind and traffic |

| 3G – High Vibration | Bridges, tunnels, high-traffic highways, seaports | Simulates severe & continuous vibration |

Lights installed in environments like the photo you provided—multi-direction adjustable arms or poles near buildings or traffic—benefit from 3G-level vibration resistance.

How the ANSI C136.31 Vibration Test Works

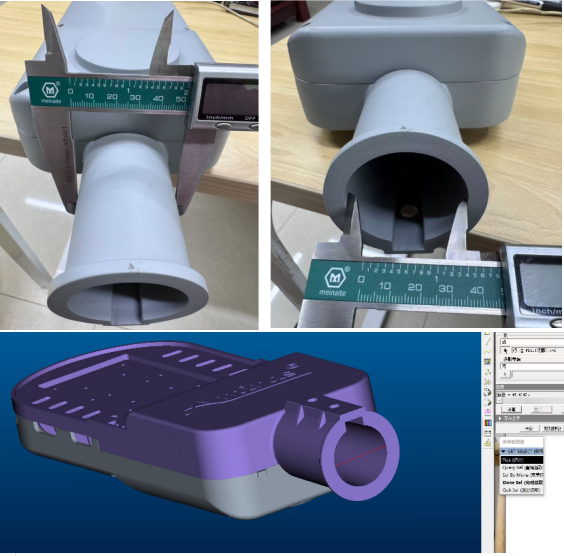

The test uses a 3-axis vibration table that applies controlled vibration across the luminaire’s key mounting points.

Test Procedure Overview

Mounting Simulation

The luminaire is installed on a rigid test fixture mimicking real pole-arm installation.Frequency Sweep

Vibrations sweep through a wide frequency range (e.g., 5–500 Hz) to identify resonance points.Sustained Vibration Exposure

The luminaire undergoes continuous vibration at specified G-forces for many hours.Post-Test Evaluation

Engineers check for:Structural cracks

Loose fasteners

Damage to optics or LED modules

Wiring/connector failure

Driver performance issues

Passing the test means the luminaire can withstand years of real-world vibration without degradation.

Key Design Features for Vibration-Resistant LED Street Lights

High-quality LED street lights integrate various design improvements to meet ANSI 2G or 3G vibration levels:

1. Reinforced Housing Structure

Die-cast aluminum with internal strengthening ribs resists flexing and cracking.

2. Anti-vibration Mounting Brackets

Secure slip-fitters and clamps designed to handle long-term oscillation.

3. Durable Driver and PCB Layout

Electronic components are fixed with shock-absorbing materials to prevent solder joint fatigue.

4. Anti-loosen Fasteners

Stainless steel hardware and lock-washer systems ensure parts don’t loosen over time.

5. Optimized Weight Distribution

A balanced center of gravity reduces pole and arm load vibration.

Benefits of ANSI C136.31-Certified Street Lights

Choosing luminaires tested to ANSI C136.31 ensures:

Longer lifespan and reduced maintenance

Safer installation—no falling parts

Stable lighting output with no flicker

Resilience in extreme outdoor conditions

Lower total cost of ownership for municipalities

For cities and developers, vibration-tested LED street lights deliver reliability and peace of mind.

Conclusion

Vibration resistance is a crucial factor in the performance and safety of outdoor LED street lights—especially in challenging environments like bridges, highways, industrial zones, or tall poles exposed to wind. The ANSI C136.31 vibration test ensures that luminaires can withstand years of mechanical stress without failing.

When choosing LED street lights, always check for 2G or 3G ANSI C136.31 certification to guarantee durability and long-term performance.

Author introduction

Author

G'day My friends,

My name is Royce O'young, I’m the sales manager of Oleder Lighting. I have been in the LED lights industry for more than 16 years. Good at lighting design, street light system configuration, and bidding technology support,and architecture inner decorating lighting advice . Feel free to contact us.I’m happy to provide you with the best service and products.

Email: r.oyoung@oleder-lighting.com | WhatsApp: +86159 2057 0517

Related Products

|  |  |

| OLEQ2 LED street Lights with ENEC prefesssional for municiple projects | OLEA1LED Flood lights familiy for architecture projects | OLEB7 LED High bay Power & CCT adjustable less your stock inventory |

CATEGORIES

CONTACT US

Contact: Royce O'young

Phone: 15920570517

Tel: 0086-20-37716973

Email: r.oyoung@oleder-lighting.com

Add: Room 335,#1 Xianke 1st Rd, Honglitronic Group,Huadu ,510890, Guangzhou,P.R.C.

Sales

Sales