Blog

Benifits and advices for Street lighting maintenance

Introduction

Street lighting refers to outdoor lighting arranged on one side, both sides or on the isolation island of the street. Its main purpose is to provide necessary visibility for pedestrians and vehicles at night, and it also plays a role in beautifying the city's night view. Street lighting devices can only operate continuously with high efficiency and provide sufficient light if they are well maintained. In order to ensure the effective operation of the road lighting system, it is important to perform regular preventive maintenance as well as timely corrective/predictive maintenance. OLEDER believes that providing regular maintenance and inspection plans for outdoor lighting devices can help your system operate normally in the next few years. At the same time, providing corrective/predictive maintenance for outdoor lighting devices can promptly eliminate adverse consequences caused by insufficient lighting. This article mainly explains why street lighting maintenance is performed, its significance and how to perform street lighting maintenance, aiming to keep your outdoor lighting system in optimal condition.

Benefit of street lighting maintenance

When road lighting fails, various problems will follow. For example, direct impacts include increased risk of traffic accidents, threats to pedestrian safety, and reduced quality of life for residents. Indirect impacts include accident compensation, indirect economic losses caused by reduced nighttime activities, and higher maintenance/repair costs in the later stage. On the contrary, the benefits of implementing and timely street lighting maintenance are also obvious. It will help to:

Increase the service life of the lighting system: Check and replace wearing parts such as surge and seals, which can prevent small problems from accumulating into major failures, thereby extending the service life of the entire lighting system.

Improve energy efficiency and reduce lighting costs: Regularly clean the surface of the lamp or replace the LED light source part to ensure that the lighting equipment is in the best working condition (high light transmittance and high LED chips light efficiency), so as to ensure that the lamp can meet the lighting needs with lower wattage to reduce energy waste.

Ensure the reasonable lighting area of the lamp: Regularly adjust the installation position and illumination angle of the lamp to ensure that the light emitted by the lamp correctly covers the area that needs to be illuminated, avoid blind spots to increase safety, and reduce unnecessary light (upward light) to reduce light pollution.

Prevent potential safety hazards such as electric shock: Regular inspection and maintenance of electronic components can ensure the integrity of cables, wiring and casing in lamps and lanterns, thereby effectively preventing electric shock accidents.

Why go with street lighting maintenance?

Street lighting fixtures can only operate continuously at high efficiency and provide sufficient light if they are well maintained. However, lighting systems will experience some degradation during use. Degradation is caused by lamp failure, lamp with less efficiency(reduction in the amount of light produced) and lamp contamination. Street lighting maintenance can delay the degradation of lamp performance and ensure continuous lighting by repairing lamps in time when they fail. Below we explain the different degradations one by one.

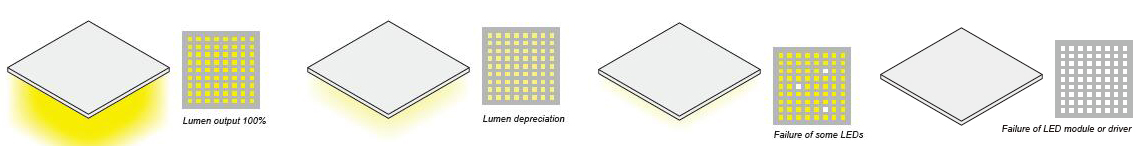

Failure of street lamps

The main manifestation of LED street light failure is that the lamp is not lit or flickers. The main reason for this type of failure is that there is a problem with the LED driver, LED module or surge. Excluding poor quality power supply and chip problems, ambient temperature, voltage fluctuations and surges, on/off switching frequency and heat dissipation problems can also cause failures. Therefore, it is necessary to conduct regular inspections and maintenance of road lighting to ensure the continued normal operation of the lamps.

Street lamps are too dim(LED light decay)

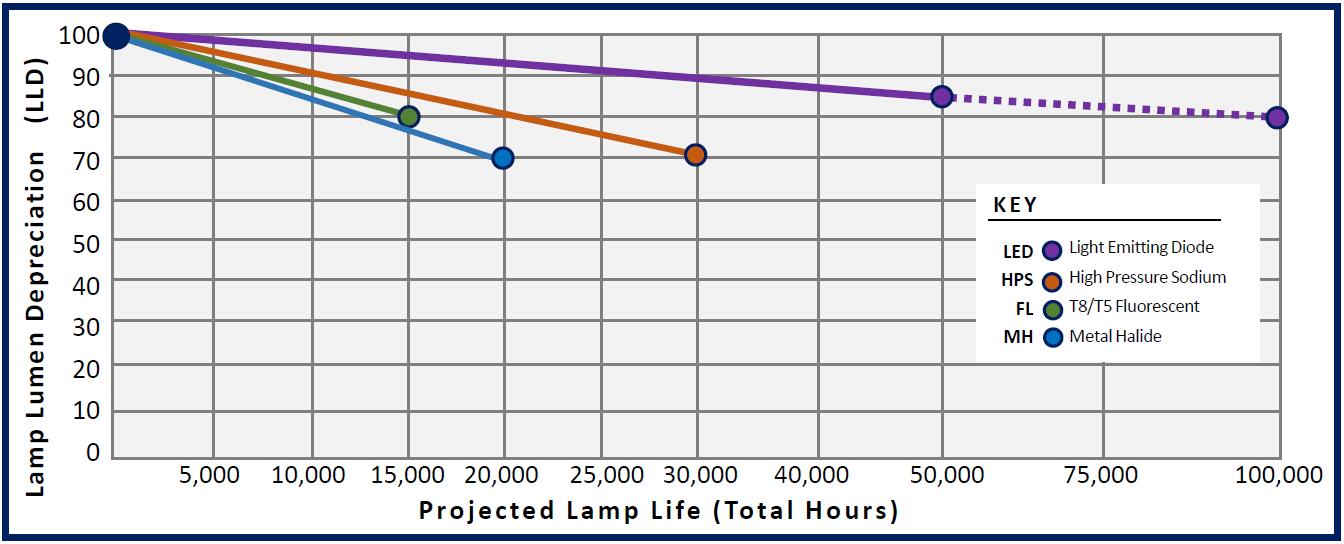

LED light decay is an inevitable phenomenon in the long-term use of LED products. Chip quality, production process, heat dissipation performance, and driving current all affect the rate of light decay. Generally, we believe that when the luminous flux of a street lamp drops to 70% of its initial luminous flux, the LED light source needs to be replaced, because 70% of the luminous flux can no longer meet the requirements of the project’s contrast/brightness at the beginning of the lighting design. Insufficient lighting will also cause various problems, so it is necessary to maintain (replace the light source) the street lamps that are not emitting enough light to ensure that the lighting in areas such as motor vehicle lanes, sidewalks, and parking lots can meet the corresponding requirements.

Street lamps are contaminated

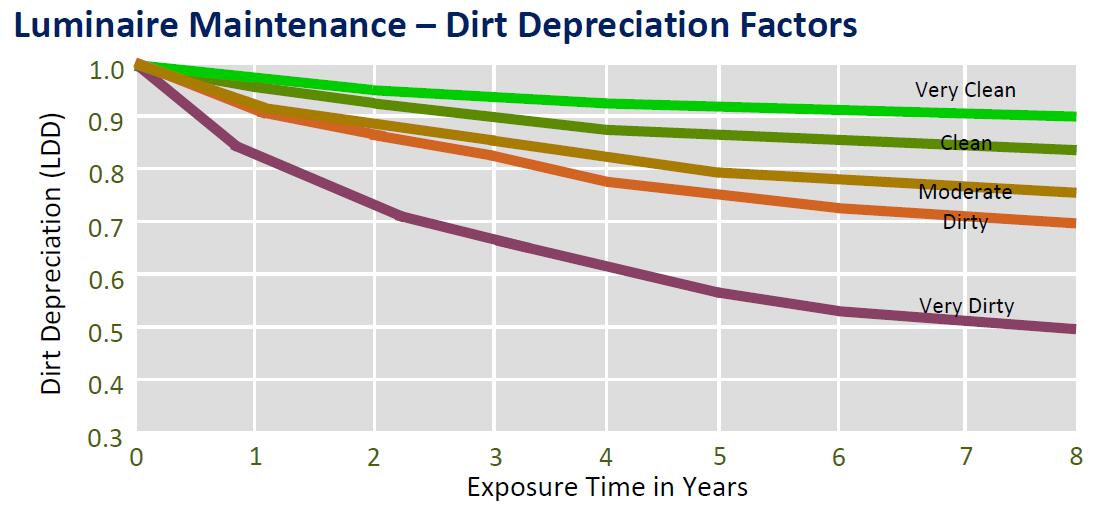

In addition to the light decay of the light source itself, another serious cause of street light loss is the accumulation of dirt on the light emitting surface of the street lamp. The severity of the dirt depends on the type of lamp, the IP code and the pollution level in the atmosphere. The lower the IP level, the more serious the light loss of the lamp will be as the lamp is installed (exposure time). LED street lamps with the same IP level will also have more serious light loss in environments with high pollution rates than in environments with low pollution rates. The total effect of these factors affecting the light decay of street lamp systems can reduce the lumen output of street lamps by 15% to 40% or even more at the end of the maintenance cycle. According to CIE 154:2003, the maintenance factors of LED lamps with different IP ratings(Lamp structure & Seal gasket design is key for waterproof) in different pollution environments are different(see below table), so it is necessary to regularly clean the surface of LED street lamps to make the light loss less serious.

Safety considerations

In addition to failures and light decay, street lamps also need to regularly check wires, connectors and grounding devices to prevent electrical short circuits or leakage accidents caused by aging, damage or poor contact of wires. At the same time, the housing of street lamps also needs to be regularly inspected to ensure that IP/IK meets the requirements to avoid the impact of reduced waterproof and anti-collision performance on the safety and performance of the lamps.

How to go with street lighting maintenance?

Replacement of LED driver

OLEDER believes that regular maintenance of LED drivers is unnecessary. Although some LED drivers are equipped with an end-of-life indicator, we still recommend spot replacement of faulty LED drivers, that is, replacement when a fault occurs. To avoid batch failure of LED drivers in LED street lights, we recommend using LED drivers produced by reliable brand suppliers so that they can provide the required current and voltage input for LEDs throughout their service life. At the same time, we recommend checking surge protection devices to ensure that LED street lights are protected from devastating blows such as lightning strikes and power grid surges.

Replacement/cleanliness of LED module

Different lamps contain different light sources, and their light decay performance varies. Generally speaking, LED light sources have the slowest and most stable light decay. High-quality LED lamps have a light decay of no more than 30% within 100,000 hours, which is very suitable for providing continuous lighting for roads and other outdoor lighting. In contrast, fluorescent lamps have a faster light decay, with light output dropping to 70-80% after 10,000-15,000 hours. In addition, frequent switching will accelerate its light decay. High-pressure sodium lamps have a relatively slow light decay, with light output dropping to about 70% after 30,000 hours. It was suitable for outdoor lighting before the large-scale application of LED lamps. Incandescent lamps have the fastest light decay and the shortest life (about 1,000 hours), mainly manifested by filament evaporation (melting) and the inner wall of the bulb turning black and unable to provide lighting. According to the calculation that the L70 (i.e. the life of the luminous flux maintenance rate of not less than 70%) of LED street lamps is greater than 100,000 hours, we will need about 20 to 25 years before considering replacing the light source. However, it is worth noting that pollution on the surface of the lamp often affects the luminous flux of the lamp more quickly, which we will introduce in detail below.

As mentioned in the previous section, LED street lights, like all lamps, are also affected by dirt. Over time, this dirt will reduce the light output. If it is an IP66 lamp, its luminous flux will drop to 0.83 of the original after 3 years in a highly polluted environment. However, at this time, the road lighting is still relatively new, so there is no need to replace the original lamps. Instead, we only need to develop a cleaning plan based on relevant empirical data or field data. For the former, we can clean the lamps according to the data provided by CIE 154:2003, and for the latter, we can clean according to the following suggestions.

1. First, we need to know the illuminance or brightness of the installed lamp and record this data.

2. a) Measure the illuminance and brightness of the same points under the lamp at a fixed time period every year. When the illuminance/brightness drops by more than 20%, try to high-pressure clean the surface of the lamp (lens or glass) from the ground. b) Measure the illuminance and brightness of different points under the lamp at a fixed time period every year. When the illuminance/brightness does not meet the corresponding lighting requirements, try to high-pressure clean the surface of the lamp (lens or glass) from the ground.

3. Continue to check lighting levels regularly and eventually implement a lamp cleaning plan based on the frequency required to maintain the required lighting level. If the illuminance/brightness still does not meet the lighting requirements after cleaning, the light source of the lamp needs to be replaced or other methods need to be used to ensure that the lighting meets the requirements.

Appearance and wiring inspection

LED street lights are used outdoors in a relatively harsh environment (rain, snow, high and low temperatures, salt spray corrosion). If conditions permit, OLEDER recommends regular inspections of the appearance and internal wiring of the lamps. The inspections include: 1. Check whether there are scratches, cracks or other physical damage on the surface of the lamp. 2. Check whether the coating of the lamp has discoloration, corrosion and detachment. 3. Check whether the structure of the lamp is firm, the screws are tightened, and the waterproof seals is intact. 4. Check whether the wiring inside the lamp is intact, whether the input line is intact, and whether there are exposed and damaged cables. Through the above inspections and necessary repairs, we can ensure the performance and safety of LED lamps.

OLEDER lighting solution

OLEQ1 STREET LIGHT SOLUTION OLEQ7 STREET LIGHT SOLUTION

CATEGORIES

CONTACT US

Contact: Royce O'young

Phone: 15920570517

Tel: 0086-20-37716973

Email: r.oyoung@oleder-lighting.com

Add: Room 335,#1 Xianke 1st Rd, Honglitronic Group,Huadu ,510890, Guangzhou,P.R.C.

Sales

Sales